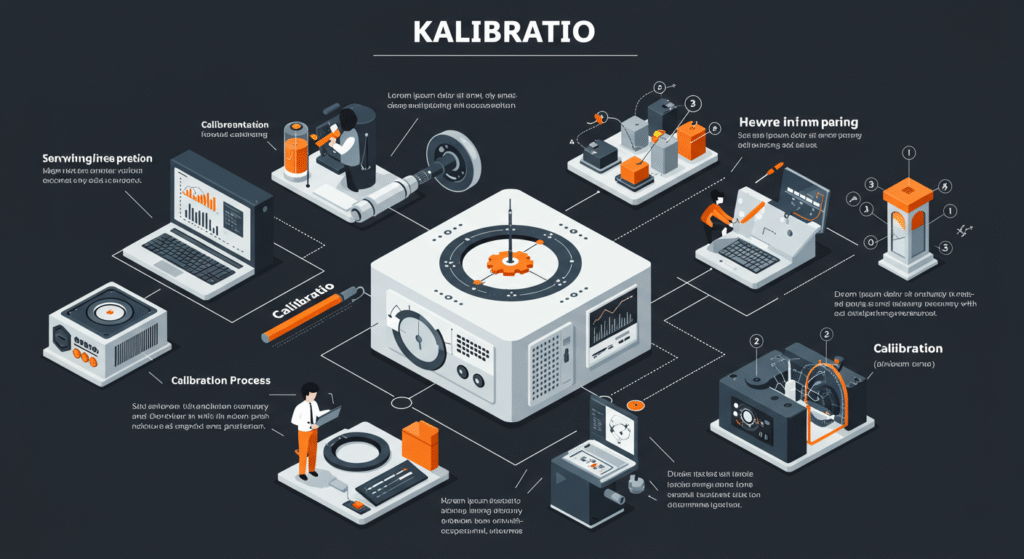

The term kalibraatio, derived from the Finnish word for calibration, refers to the process of adjusting, testing, and verifying the accuracy of instruments and systems. In simple terms, kalibraatio ensures that a device or system performs according to a defined standard. Whether in laboratories, industrial machinery, or digital measurement tools, kalibraatio plays a crucial role in maintaining accuracy, reliability, and consistency.

Modern industries depend heavily on precise data and performance. Therefore, kalibraatio becomes an integral part of quality assurance, helping detect deviations, prevent errors, and ensure safety in all operations.

Understanding the Concept of Kalibraatio

Kalibraatio involves comparing the measurements of a device against a known reference standard. If the device shows a discrepancy, adjustments are made until it aligns perfectly with the reference value. This process helps maintain the integrity of instruments used in various fields such as healthcare, manufacturing, engineering, and electronics.

| Aspect | Details |

|---|---|

| Definition | Kalibraatio is the process of verifying and adjusting the accuracy of instruments. |

| Objective | To ensure devices produce accurate and consistent results. |

| Examples | Calibration of thermometers, pressure gauges, and electronic sensors. |

| Frequency | Regularly performed based on equipment usage and environment. |

Without proper kalibraatio, even the most advanced instruments can yield misleading data, resulting in costly errors or system failures.

Types of Kalibraatio

There are several types of kalibraatio, depending on the nature of the instrument and the field of application.

1. Mechanical Kalibraatio

Mechanical kalibraatio involves testing and adjusting devices that measure physical properties such as pressure, force, or torque. For instance, a torque wrench used in automotive repair must undergo kalibraatio to ensure it applies the correct amount of force.

2. Electrical Kalibraatio

This form of kalibraati deals with electrical measuring instruments like voltmeters, ammeters, and multimeters. By comparing these devices to known electrical standards, professionals ensure they produce accurate readings essential for electronic circuit testing and maintenance.

3. Thermal Kalibraatio

Thermal kalibraaio focuses on temperature-measuring devices such as thermocouples, thermostats, and infrared sensors. Since temperature affects numerous industrial and scientific processes, maintaining accurate calibration is vital for efficiency and safety.

4. Dimensional Kalibraatio

Dimensional kalibratio involves tools that measure length, width, or thickness — such as calipers, micrometers, and rulers. This process is especially critical in manufacturing industries where precision determines the quality of the final product.

The Process of Kalibraatio

The kalibraatio process typically follows several essential steps to ensure accuracy and compliance with standards.

| Step | Description |

|---|---|

| 1. Preparation | Gather reference standards and ensure environmental conditions are stable. |

| 2. Measurement | Compare the instrument’s readings against the standard. |

| 3. Adjustment | If differences exist, fine-tune the device until results align. |

| 4. Documentation | Record all measurements, results, and adjustments for verification. |

| 5. Verification | Recheck to confirm accuracy after adjustments. |

Following these steps guarantees that the kalibratio meets both national and international standards such as ISO/IEC 17025, which governs testing and calibration laboratories.

Why Kalibraatio Is Important

The importance of kalbraatio extends beyond mere accuracy. It supports efficiency, safety, and compliance in every technical field.

1. Accuracy and Reliability

Regular kalibraatio ensures that instruments deliver reliable data, which forms the foundation for decision-making in industries like healthcare, aviation, and manufacturing.

2. Safety and Compliance

In environments where precision determines safety—such as nuclear plants or hospitals—proper kalibaatio can prevent accidents and ensure compliance with regulatory requirements.

3. Cost Efficiency

Although it may seem time-consuming, kalibaatio helps reduce long-term costs by minimizing equipment downtime, preventing product defects, and avoiding legal penalties for non-compliance.

4. Quality Assurance

Accurate measurements are essential for maintaining product quality. Through regular , companies maintain the integrity of their production processes, ensuring customer satisfaction.

Applications of Kalibraatio in Different Fields

The scope of spans across various sectors, each depending on its precision and accuracy.

| Field | Application |

|---|---|

| Healthcare | Calibration of medical devices like blood pressure monitors, thermometers, and infusion pumps. |

| Manufacturing | Ensures machinery and measuring tools meet production standards. |

| Aerospace | Used in the calibration of navigation and flight instruments. |

| Automotive | Ensures torque, pressure, and temperature sensors function accurately. |

| Telecommunications | Calibration of signal measuring equipment and network analyzers. |

Every sector relies on to maintain safety, performance, and regulatory compliance.

Best Practices for Effective Kalibraatio

To achieve the best results, professionals must follow specific kalibraaio best practices:

-

Regular Scheduling: Establish a consistent calibration schedule based on equipment usage and manufacturer recommendations.

-

Use Certified Standards: Always use traceable and certified reference standards to ensure international compliance.

-

Environmental Control: Maintain stable temperature, humidity, and lighting during the kalbraatio process.

-

Qualified Personnel: Ensure calibration is performed by trained and certified technicians.

-

Detailed Documentation: Keep accurate records of all calibration results, adjustments, and procedures.

These practices enhance the reliability and traceability of every kalibraati process, supporting long-term operational efficiency.

Challenges in Kalibraatio

Despite its importance, kalibraato can face challenges such as environmental changes, equipment wear, or lack of proper documentation.

-

Environmental Influence: Temperature and humidity fluctuations can affect measurements.

-

Instrument Drift: Over time, instrument components may degrade, leading to deviations in readings.

-

Human Error: Improper handling or incorrect reference standards can result in inaccurate calibration.

Addressing these challenges requires adopting automation, digital tracking, and periodic re-calibration strategies to maintain precision.

Future Trends in Kalibraatio

As technology evolves, the future of kalibratio lies in automation and digital transformation. Advanced calibration systems now use artificial intelligence (AI) and Internet of Things (IoT) technologies to monitor and adjust instruments remotely.

Smart sensors, automated calibration software, and blockchain-based record systems are revolutionizing how industries manage and track calibration data. These innovations not only improve accuracy but also make kalibratio faster, more efficient, and more sustainable.

Conclusion

In conclusion, kalibraatio serves as the backbone of precision and reliability in today’s technology-driven world. From scientific research to industrial production, it ensures every measurement and operation meets strict accuracy standards. By following proper calibration methods and maintaining consistent schedules, organizations can achieve higher efficiency, quality, and safety.

As industries move toward automation and smart systems, the role of will continue to grow—helping maintain the delicate balance between technology and trust.