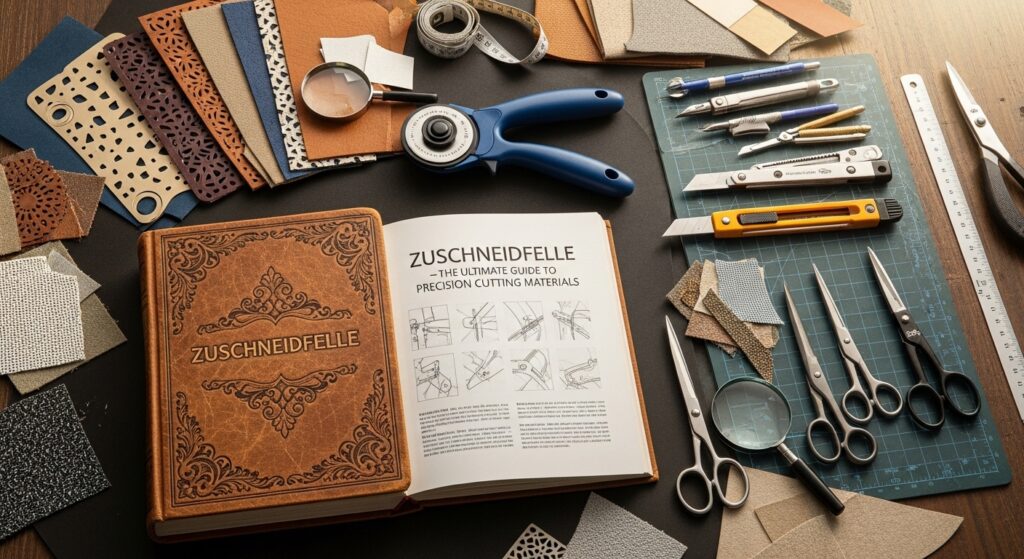

In modern manufacturing, craftsmanship, and design, the word Zuschneidfelle holds a special place. It translates from German to “cutting skins” or “cutting materials,” representing precision sheets or hides used for various cutting and crafting purposes. Zuschneidfelle are widely applied in industries such as textiles, leather production, furniture, and even automotive design, where precision and material integrity are crucial.

Understanding Zuschneidfelle means exploring the combination of durability, flexibility, and precision. Whether synthetic or natural, these materials are crafted to ensure clean, efficient cuts during manufacturing processes. In this article, we’ll explore their properties, applications, classifications, and benefits, along with a helpful comparison table to guide you in choosing the right type of Zuschneidfelle for your needs.

What is Zuschneidfelle

The term Zuschneidfelle describes sheets or hides of materials designed specifically for cutting and shaping. These are essential components in both manual and machine-based cutting systems. Their purpose is to act as a protective and stabilizing layer under cutting tools, ensuring precision without damaging the blade or underlying surface.

Typically, Zuschneidfelle are made from high-quality materials such as leather, synthetic rubber, or polyurethane. Each variant has distinct characteristics that make it suitable for specific industrial or artisanal tasks.

Importance of Zuschneidfelle in Modern Industry

The role of Zuschneidflle extends far beyond simple cutting mats or sheets. They contribute to production accuracy, material longevity, and cost efficiency. When manufacturers or artisans use Zuschneidfelle, they minimize errors and ensure smoother edges and surfaces on the final product.

Here are some industries where have significant importance:

-

Textile Industry: Used as base materials for cutting fabrics precisely.

-

Leather Industry: Essential for cutting patterns and designs from raw hides.

-

Automotive Sector: Applied in crafting seats, upholstery, and interiors.

-

Furniture Making: Ensures even, smooth cuts on cushioning materials.

-

Craftsmanship and Design: Offers surface stability for intricate cutting tasks.

Key Features of Zuschneidfelle

The effectiveness of lies in its properties. These features determine the type of applications it can support.

| Feature | Description | Benefit |

|---|---|---|

| Durability | Resistant to cuts and abrasions | Ensures long-lasting performance |

| Elasticity | Flexes slightly under pressure | Prevents blade damage |

| Smooth Surface | Non-slip, even texture | Enables accurate cutting |

| Material Compatibility | Works with leather, fabric, foam, etc. | Enhances versatility |

| Maintenance | Easy to clean and reuse | Reduces operational cost |

Each of these characteristics makes an irreplaceable tool in workshops and factories where precision cutting defines the quality of the final product.

Types of Zuschneidfelle

Different projects require different kinds of Zuschnedfelle. Understanding their classification helps in choosing the right material for optimal results.

1. Natural Zuschneidfelle

Natural are made from real leather or hides. They offer a traditional and robust feel, often preferred by artisans for their texture and longevity.

Key Traits:

-

High resistance to cuts and pressure

-

Naturally non-slip surface

-

Suitable for luxury craftsmanship

2. Synthetic Zuschneidfelle

These are manufactured using synthetic materials like polyurethane, PVC, or composite rubber. They are lighter, more affordable, and easier to clean.

Key Traits:

-

Uniform texture for smooth cutting

-

Resistant to water and chemicals

-

Ideal for industrial applications

3. Hybrid Zuschneidfelle

A blend of both natural and synthetic components, hybrid aim to balance the durability of natural leather with the flexibility of modern synthetics.

Key Traits:

-

Balanced performance

-

Environmentally adaptive

-

Cost-effective solution

Applications of Zuschneidfelle

The versatility of makes it applicable in numerous professional and artistic fields. Below is a table showing how different industries use this material.

| Industry | Application | Material Preference |

|---|---|---|

| Textiles | Cutting precision patterns | Synthetic Zuschneidfelle |

| Leather Goods | Crafting bags, belts, wallets | Natural Zuschneidfelle |

| Automotive | Upholstery and seat cutting | Hybrid Zuschneidfelle |

| Furniture | Foam and fabric trimming | Synthetic Zuscneidfelle |

| Footwear | Shoe pattern and sole cutting | Natural Zuschneidfelle |

Each industry relies on for accurate results, reducing material waste and increasing efficiency.

How to Maintain Zuschneidfelle

Maintenance of Zuschneidfele is essential to ensure its longevity and effectiveness. Proper care also prevents uneven surfaces or wear that can affect cutting precision.

Maintenance Tips:

-

Clean the surface regularly with mild soap and water.

-

Avoid exposure to direct sunlight or high heat.

-

Store flat to prevent bending or cracking.

-

Check for surface damage before each use.

-

Replace when deep cuts or grooves appear.

Benefits of Using Zuschneidfelle

Using provides several practical and economic advantages in production and crafting environments.

-

Enhanced Accuracy:

The smooth surface of ensures that each cut follows the exact design or pattern intended. -

Blade Protection:

These materials absorb the blade’s impact, preventing dulling or breakage. -

Reduced Material Waste:

With precise cutting, there’s less need for material correction, leading to cost savings. -

Safety and Stability:

Non-slip surfaces help maintain control during manual cutting. -

Eco-Friendly Options:

Many manufacturers now offer recyclable or sustainably produced Zuschnidfelle.

How to Choose the Right Zuschneidfelle

Selecting the perfect depends on your intended use. The table below compares major types based on features and applications.

| Type | Durability | Flexibility | Ideal Use | Cost |

|---|---|---|---|---|

| Natural Zuschneidfelle | High | Medium | Leather Craft | $$$ |

| Synthetic Zuschneidfelle | Medium | High | Industrial Work | $$ |

| Hybrid Zuscneidfelle | High | High | Automotive, Furniture | $$$ |

When purchasing, also consider factors like cutting frequency, blade type, and workspace environment.

Future of Zuschneidfelle in Manufacturing

With the advancement of technology and sustainable production methods, Zuschnidfelle are evolving rapidly. Smart materials with self-healing surfaces or embedded cutting guides are being developed to improve cutting accuracy and tool protection.

Eco-conscious production is another major trend. Many companies now use recycled or bio-based materials to manufacture , reducing environmental impact while maintaining superior performance.

As industries adopt automation and digital cutting systems, will continue to play a vital role in balancing traditional craftsmanship with modern efficiency.

Conclusion

Zuschneidfelle represent more than just cutting materials—they embody precision, craftsmanship, and industrial innovation. From traditional leather crafting to high-tech manufacturing, these materials provide the foundation for smooth, accurate, and efficient cutting.

By understanding the different types, properties, and applications of Zuscneidfelle, professionals can make informed decisions that enhance productivity and ensure top-quality results.

Whether you’re a designer, artisan, or manufacturer, incorporating the right into your workflow guarantees better outcomes, longer tool life, and superior material handling in every project.