Industrial wheels and casters are at the heart of efficient facility operations, serving as essential components in everything from manufacturing plants to healthcare facilities. The right choice of caster, such as a durable phenolic wheel, not only streamlines workflows but also helps address long-standing challenges in safety, mobility, and productivity in demanding environments.

As industrial facilities evolve to handle larger volumes and greater complexity, technological advancements in wheels and casters become increasingly significant. Facility managers are now focusing on integrating innovative caster solutions to maximize efficiency and extend the lifespan of their valuable equipment. By supporting both manual and automated systems, modern wheels and casters underpin critical logistics and operations, ensuring businesses remain agile within a rapidly changing marketplace.

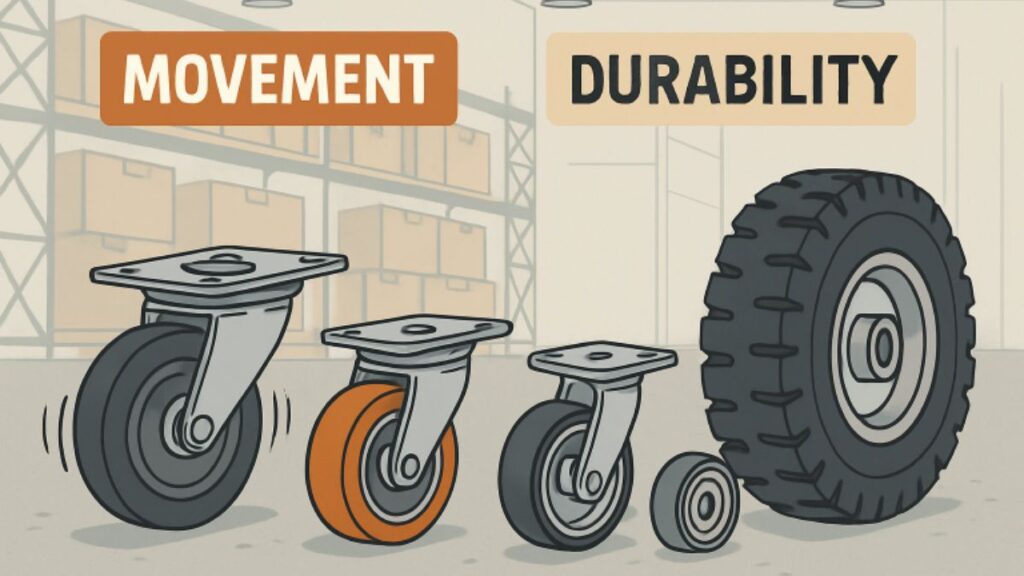

Enhancing Mobility and Efficiency

Facility operations depend heavily on efficiency, especially in material transportation and handling. Modern casters enable smooth, controlled movement of even the heaviest loads, reducing physical strain on workers and minimizing delays. The adoption of advanced wheel designs has made it easier to maneuver equipment in tight spaces, improving workflow and reducing workplace injuries. Warehouses and distribution centers, in particular, have seen notable boosts in productivity and speed, thanks to enhanced caster technology.

For businesses dealing with frequent movement of large or sensitive inventory, reliability and ease of use are paramount. Ergonomically designed casters reduce the force required to move carts, racks, and machinery, allowing staff to focus on higher-value tasks.

Advancements in Materials and Design

The shift toward high-performance materials, such as reinforced nylon and advanced polyurethanes, has significantly increased the durability and load-bearing capacity of industrial wheels. Manufacturers are now producing casters that withstand the harshest of conditions, from high temperatures to corrosive chemicals, making them suitable for a broader range of sectors. The design enhancements—such as sealed bearings that keep out debris or grease fittings that extend component lifespan—ensure ongoing reliability and minimize costly downtime.

Furthermore, the development of anti-microbial and conductive wheels supports compliance with strict industry standards in healthcare, electronics, and food processing. These advancements are vital for maintaining hygienic, safe workspaces and helping facilities avoid unnecessary suspensions of operations due to contamination risks.

Noise Reduction and Workplace Safety

Workplace sound levels are a growing concern for facility managers, as excessive noise contributes to employee discomfort and potential hearing loss. Moreover, casters with special tread materials or ergonomic designs reduce the risk of tipping and accidents, directly enhancing worker safety on the floor. By prioritizing quiet, stable, and secure movement, companies demonstrate their commitment to employee well-being—an element that can boost morale and decrease turnover.

Customization for Industry-Specific Needs

No two industries are exactly alike, and neither are their caster requirements. Sectors such as pharmaceuticals require anti-static and non-marking casters, while food processing demands washdown-ready components to maintain cleanliness standards. Caster manufacturers now offer a broad range of customization options, allowing facility managers to select features such as specific tread compounds, wheel sizes, and mounting hardware best suited to their application.

This trend toward customization ensures compliance with sector-specific regulations, optimizes daily workflow, and maximizes both asset longevity and operational uptime. It also empowers facilities to scale or adapt their operations without an extensive equipment overhaul.

Integration with Automation

Automation is reshaping how materials flow through modern facilities. Advanced casters and wheels are now being integrated into automated guided vehicles (AGVs), conveyors, and robotic workstations. These integrations result in unprecedented precision and speed in material handling, reducing human error and enabling round-the-clock operations with minimal intervention. The seamless collaboration between automated systems and mobility solutions not only increases throughput but also reduces labor and maintenance costs.

Sustainability and Eco-Friendly Manufacturing

As sustainability moves to the forefront of global business priorities, the caster industry is embracing eco-friendly innovation. This includes the use of recycled raw materials, low-impact manufacturing techniques, and long-life designs that minimize waste. Companies now produce wheels and casters that are not only robust but also made with environmental responsibility in mind.

These advances reduce a facility’s overall carbon footprint and are a mark of progress for companies committed to green initiatives. Adopting sustainable practices also resonates with increasingly conscientious consumers, helping build brand loyalty and securing long-term business relationships.

Conclusion

Industrial wheels and casters continue to shape the future of facility operations, underpinning advances in mobility, safety, customization, and sustainability. By staying at the forefront of material science, ergonomic design, and automation, these essential components remain critical to operational excellence and competitiveness in diverse industries.